So a while back, I was watching this video of Ryan Cleckner setting up a scope on a Remington 700:

I thought that was a neat trick with the wood cheek riser. It stuck with me. When I threw together the “assassins kit in pretty much every action movie in the 80s” as commenter Michael put it, I noticed that the while the iron sights on the 10/22 are naturally where my eyes sit when I have a good cheek weld, the scope is…well it’s a little high.

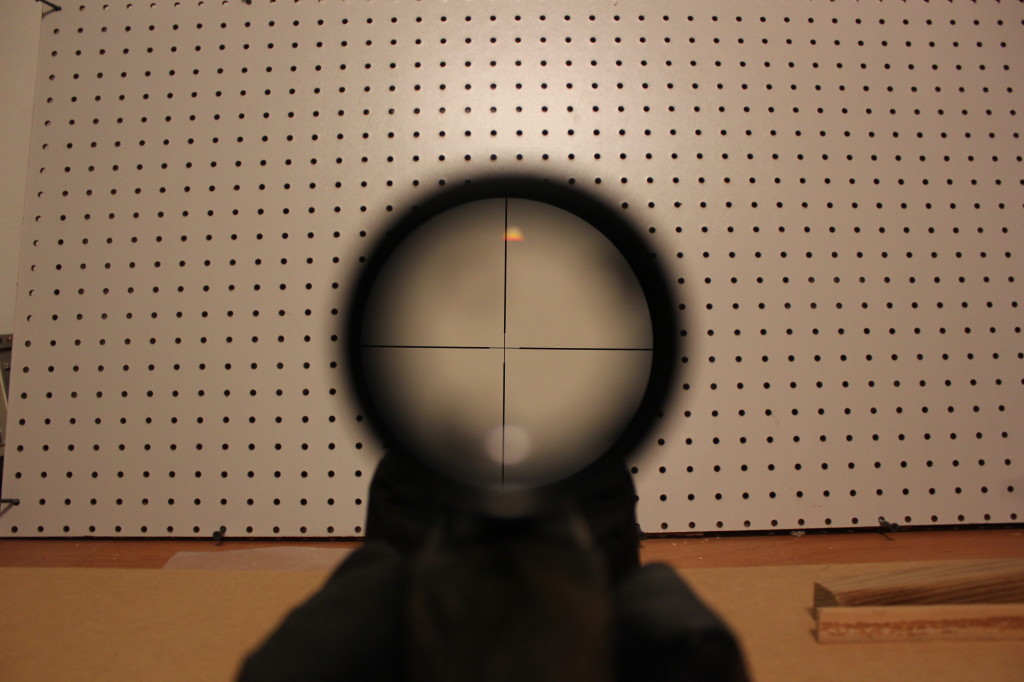

Okay so maybe it’s a lot high. I don’t know what the hell I’m doing as far as precision rifle shooting (yeah yeah it’s a .22lr–but fundamentals are fundamentals) so I’ve been trying to educate myself. In the Magpul Precision Rifle, the instructor says that the pressure your cheek puts on the stock of the rifle is “about like you’d do if you were going to sleep.” I had to move up enough to get my eye lined up with the scope that my chin was barely on the stock. That can’t be good for consistency.

I may not know what I’m doing, but Ryan Cleckner does. So I copied him. I bought an Allen Company Buttstock Shell Holder and Pouch because it looks a whole helluva lot like the one he uses.

And then I pretty much did exactly what he described:

First I started off with a couple of pieces of 1″ thick (actual) decking that were seven or so inches long and a wood shim. I didn’t want to carve on something all day.

Then I put the pieces on the stock by sliding them underneath the pouch. I didn’t really get a good picture of that but you get the idea:

The short piece of decking was a little too short:

And the longer one was just a wee bit too short:

But the combo of the short decking and the shim was about as perfect as can be:

And with the pad on, you can see how closely it lines up:

So with that all figured out, it was time to…*dramatic pause*…drill into the stock of my brand new gun.

First I put pilot holes in the shim where I was going to eventually put the nails.

Then, I taped the shim in place on the stock:

And then drilled the holes.

Now the above picture is a little deceiving. The line down the top of the stock is not actually a centerline. It’s just where the paint dip stopped..

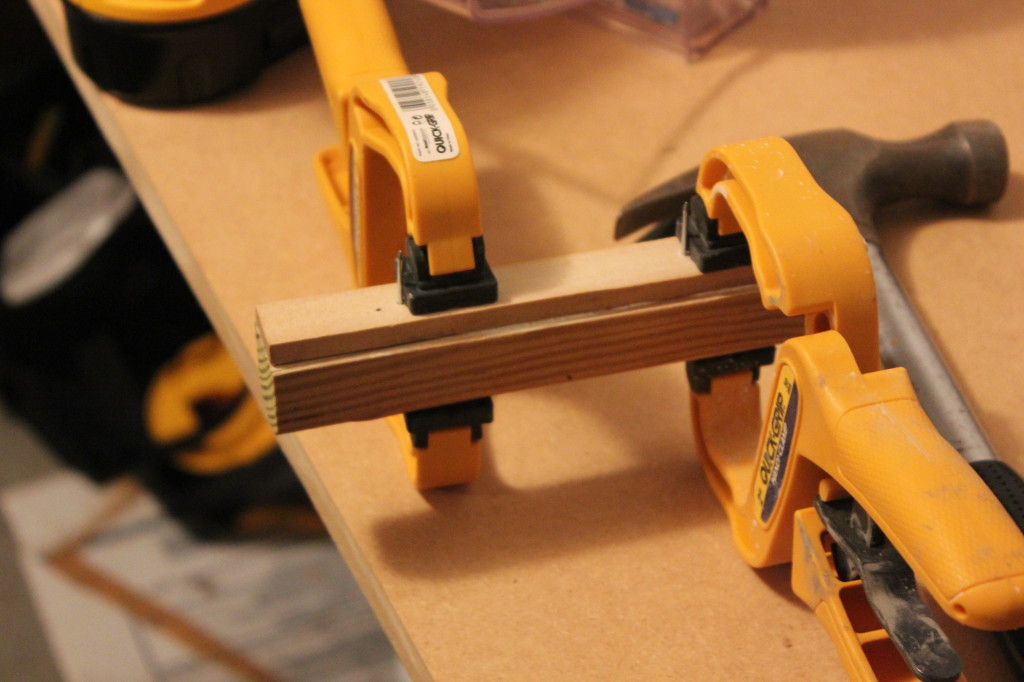

With the holes drilled, i put the nails back in and glued the two pieces together. Elmer’s wood glue, clamped overnight, because an old carpenter told me to do that and old dudes know stuff so i listen to them:

After that? Press it in and cinch down the pouch. Easy Peasy!

I’ll do the same thing on my 700 after I get my scope mounted.

Good job!

A cheek riser made a huge difference in the accuracy of my CVA muzzle loader and my 22 rifle. For my Winchester M70, I used a lace-on cheek pad similar to yours but used Strips of EVA foam from Hobby Lobby cut to 1.5″ by 6″ built up to raise the comb the required amount. I used double-sided tape to stick them together and to stick them to the cheek pad and then laced it on. Works like a charm! I used a Bear Tooth cheek pad kit for the 22 and I’m in the process of making a riser out of Kydex for the CVA.